Seed Coating with Micronutrients

- Critical Early-Stage Nutrition When Seeds Need It Most

Apply micronutrients directly to seeds for stronger roots, better drought tolerance, and improved performance.

Why Seed Coating?

Seed coating applies micronutrients directly to the seed surface, ensuring immediate availability during the critical germination and early development phases when traditional soil applications may be unavailable or inefficient.

Key Benefits:

- Immediate nutrient availability during the vital first days of germination

- Targeted delivery directly to the developing seedling when it matters most

- Enhanced early roots leading to improved drought tolerance

- Optimized nutrient efficiency

When plants receive optimal micronutrient levels right from germination, they establish stronger root systems capable of reaching deeper moisture reserves—creating natural drought insurance for your crop investment.

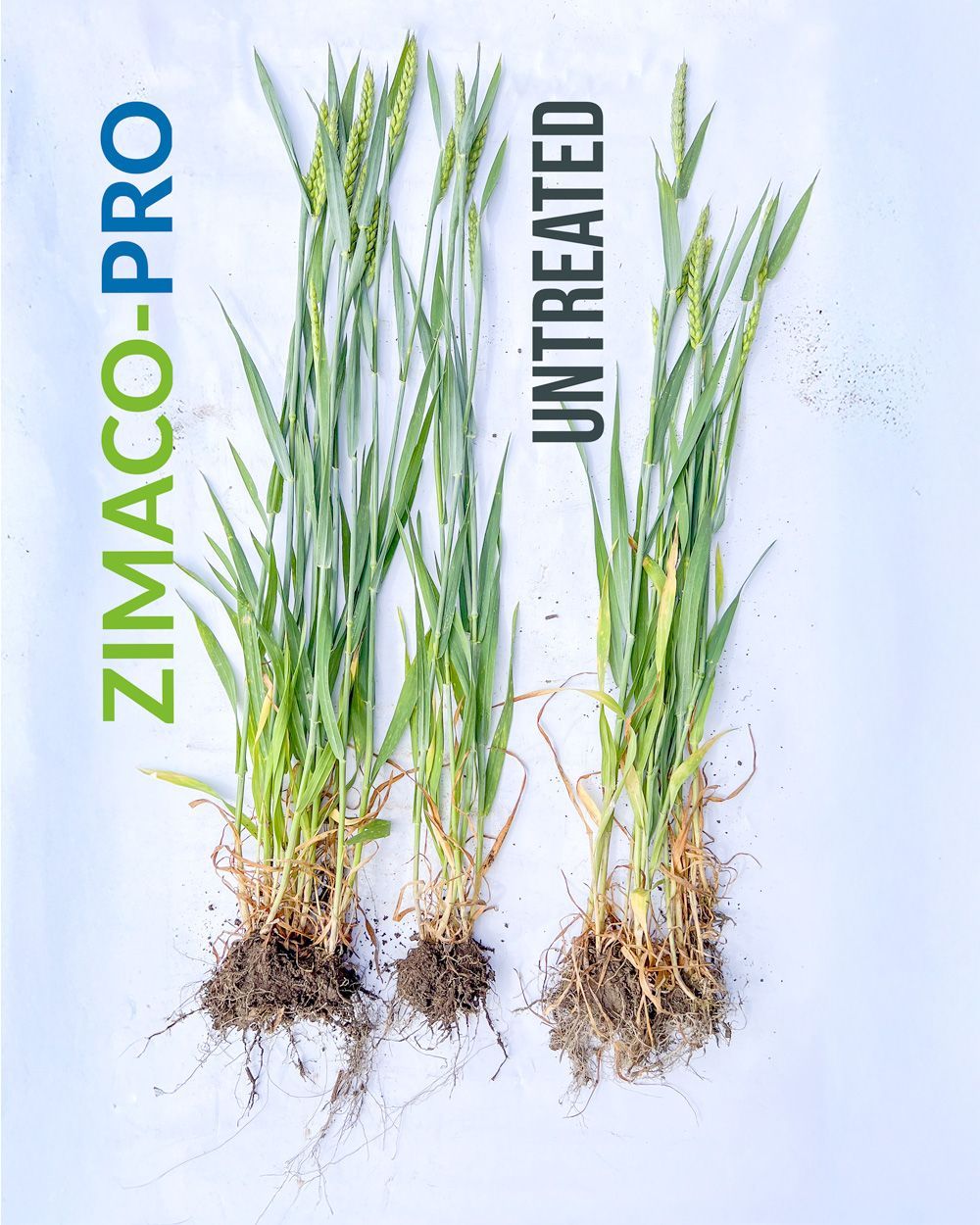

Wheat trial showing stronger root and shoot growth with ZIMACO-PRO coating.

Differences observed between treated and untreated seeds:

- Longer secondary roots: supported by zinc, manganese, and copper

- Denser root system: soil around roots stays moist and clings more tightly

- Enhanced growth: slightly taller plants at the same growth stage

- Greener lower leaves: better tolerance to dry conditions

- Stronger secondary roots: allow the plant to access nutrients and moisture from deeper in the soil, supporting better growth even in dry conditions.

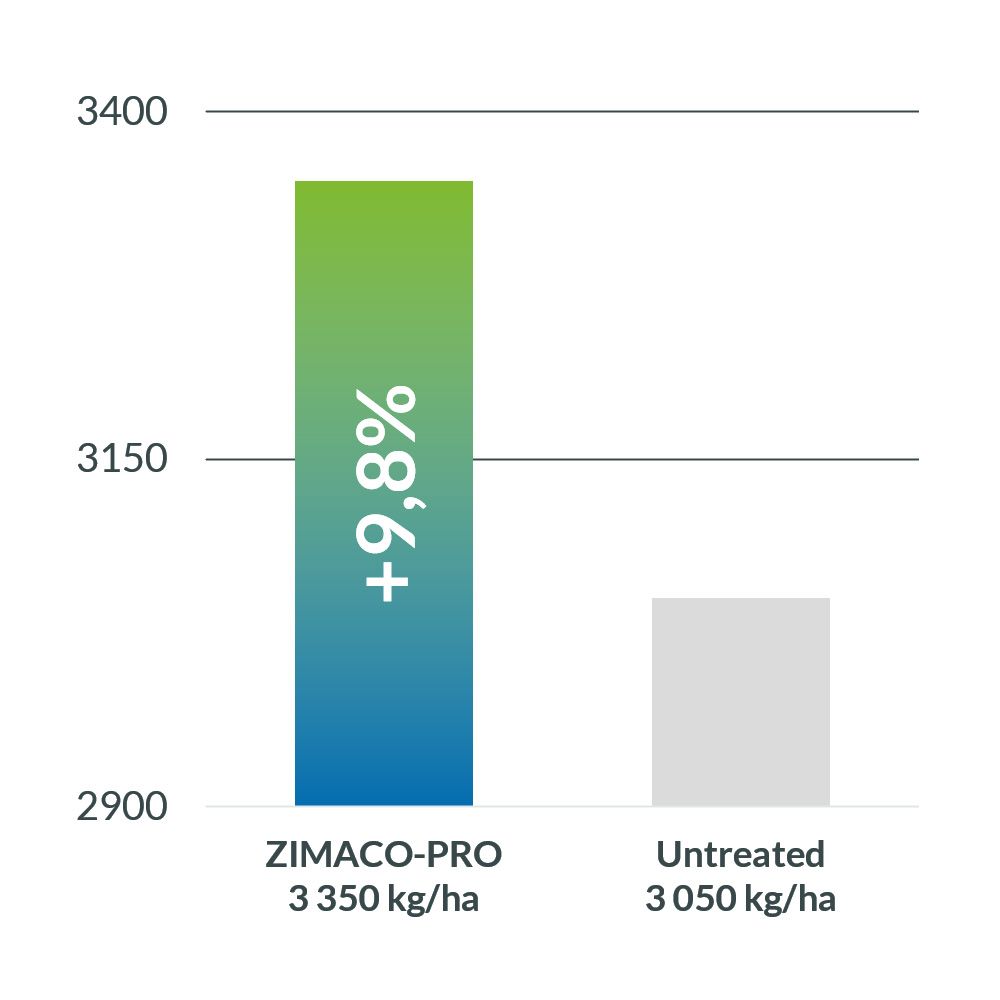

Backed by Data: Real Farm Trials

Proven performance in real farm trials

Our seed-applied micronutrients have been tested across multiple crops and growing conditions. Field trials show clear benefits in early growth and yield.

YIELD INCREASE: 300 kg/ha

PRODUCT

ZIMACO-PRO

Variety

Ceylon

Finland

Farm

Dosage / application

Coating 2 L / 1000 kg of seeds

Water / application

150 L

Applications

Coating

Notes:

Very dry season:

- No rain in May

- 20mm of rain in June

- 50mm of rain in July

Practical Advantages for Coating and Handling

Supports early crop growth

Zinc, manganese, and copper help activate growth enzymes and form stronger roots from the start.

Prevents seeds from sticking

No clumping — seeds stay free-flowing for smooth handling and sowing.

Excellent flowability

Works with most seed coating and sowing equipment without clogging.

Compatibility that saves time

ZIMACO-PRO is highly compatible with most inoculants and seed treatments due to its chelated copper. ZM-GROW and ZMC-GROW may require compatibility testing.

Easy to apply

Use 2–4 L per 1000 kg of seed — suitable for many crops and machines.

Made in the EU from recycled materials

Micronutrients come from European side streams and are processed under strict quality standards.

Seed Coating Products

Tracegrow’s micronutrient fertilisers are available as liquid seed coatings. These CE-certified products are easy to apply and compatible with most seed treatment systems.

Product

Best for

Micronutrients

Tracegrow’s seed coating products are available in 10L and 1000L canisters for professional and large-scale use.

Frequently Asked Questions About Tracegrow Seed Coating

Which crops benefit most from these coatings?

Tracegrow seed coatings improve crop performance across wheat, barley, oats, rye, oilseeds, and forage crops. In field trials, ZIMACO-PRO increased wheat yield by 300 kg/ha, and malt barley by 589 kg/ha, even in dry seasons. Oat trials showed yield increases of up to 18.5%, thanks to better root growth and nutrient uptake.

Do they help in dry conditions?

Yes. Trial results show stronger secondary root growth allows plants to access deeper moisture. In dry seasons with only 20–50 mm of rain, ZIMACO-PRO still delivered yield gains of 9.8% in wheat and 17.9% in barley, by supporting root development and stress tolerance from early growth stages.

Can these be combined with other seed treatments?

ZIMACO-PRO is compatible with most commercial seed treatments, including fungicides, inoculants, and polymer coatings, thanks to its chelated copper formulation.

ZMC-GROW and ZM-GROW are not chelated and may interact with some products — we recommend conducting a bench test or consulting our team before mixing.

What’s the optimal application rate?

Apply 2–4 L per 1000 kg of seed. Higher rates offer added support in difficult conditions. Our water soluble fertiliser ensures even distribution and cost-efficient performance, even at lower volumes.

Will it affect seed flow or block machinery?

Not at all. Tracegrow coatings bind directly to the seed with no dust or residue. Independent tests confirm excellent flow rates — even in high humidity — across all major drilling systems.

Are the products approved for organic production?

Yes. Tracegrow coatings meet EU organic farming standards and carry full CE certification. Our patented circular process turns industrial sidestreams into high-purity micronutrients — reducing emissions by up to 90%.

Where are the products made?

All Tracegrow products are manufactured in Europe under ISO-certified conditions. Each batch undergoes lab testing to guarantee purity, performance, and full traceability.All our products are CE certified.

Do you support white-label or bulk use?

Yes. We offer 10L and 1000L packaging for large-scale use, with white-label and OEM options. Our team can support distributors with regulatory documentation and technical onboarding.